For manufacturing, we used a combination of in-house methods, outsourced jobs, and off-the-shelf components. Managing the budget was the trickiest part.

- Protolabs: For high-precision and geometrically complex components such as the terrained end-plates, we outsourced our manufacturing jobs to Protolabs. Raw materials and shipping costs were all included in the order. This was by far the most expensive manufacturing method we used, but there were not many cheaper alternatives for the same quality.

- Bay Area Circuits: All custom PCB designs were sent to Bay Area Circuits, a local PCB manufacturer. These jobs were also expensive, especially when rush-ordered. Cost could have been saved if we had followed a tighter schedule.

- Anodization: Our surface finish for all of our aluminum parts were anodization. This was to prevent corrosion and electrical conduction on the surface of our parts. This job was also outsourced to a local business.

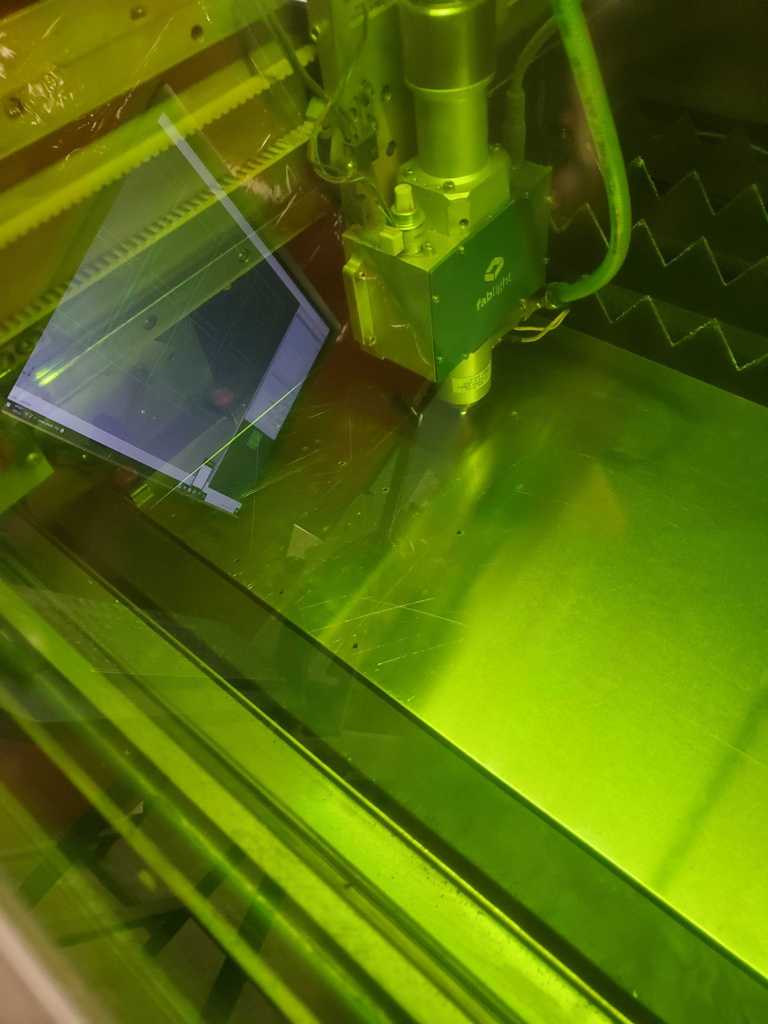

- Laser Cutters (Jacobs Makerspace): All 2-D components were laser cut in Berkeley’s makerspace: Jacobs Hall. This was an extremely efficient and economic option. The only costs incurred were the stock sheet material purchased online from McMaster as. There was no time overhead either, since we cut them ourselves.

- Etcheverry Machine Shop: Another extremely efficient and economic option was to use the machine shops on campus. Most of the tools there required training, but we could submit job requests to the staff members and have simple brackets and rods made for free. Time overhead did exist, but usually jobs were completed quickly.

- 3-D printers (personal): 3-D printers were the go-to option for prototyping. Extremely fast, versatile, and most importantly free (aside from the filament). I could get parts made from home on my personal printer.

- McMaster Carr / Ace Hardware: All loose components such as nuts, bolts, washers, and standoffs OR stock material such as sheet metal and rods were purchased either online from McMaster Carr, or off-the-shelf from the Berkeley Ace Hardware. Both were cheap and convenient options for materials and components we needed in bulk quantity.

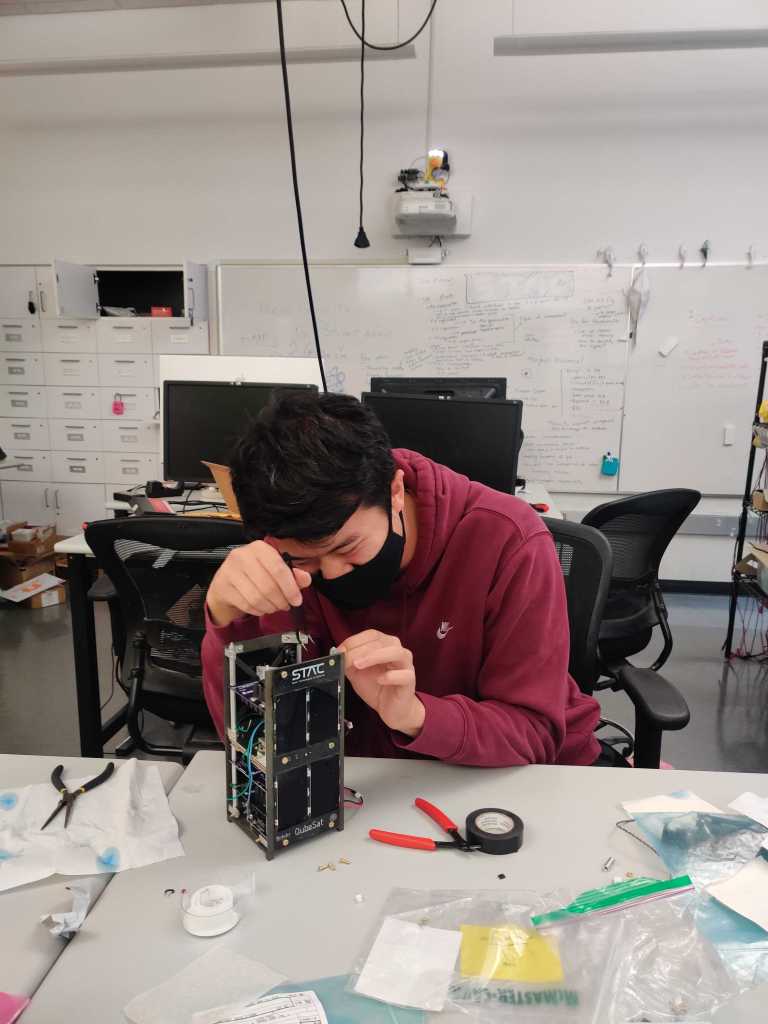

Assembly Photos!