Helicopters was an event which I only dabbled in during my years as a Science Olympiad competitor. Due to my responsibilities in other events, our competition designs were always constructed by one of my teammates. However, I did build my fair share of Helicopters on my own just for kicks. This particular design is, in my opinion, my most interesting design and by far the one I enjoyed constructing the most.

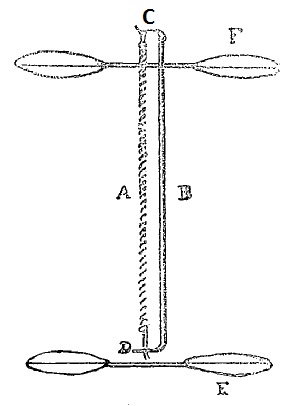

For anyone who is unfamiliar with the classic design of these helicopters, I will explain briefly as well as redirect you to this link so you can check out the specifications yourself. The classic design that had reliably worked for competitors for years involved two co-axial rotors that rotate in opposite directions. Each rotor was comprised lightweight frame/ribbing and coated with an ultra-thin Mylar film. The power comes from a large rubber band loop which has been twisted hundreds of times and attaches to the two rotor hooks. A rigid balsa beam that is slightly offset from the center axis of the two rotors was used to connect the two rotors together. The competitor would traditionally hold the two rotors still during setup and simply walk to an open indoor space and release the helicopter for flight.

In fact, this design became so reliable that Science Olympiad created its own step-by-step kit that contains all the necessary materials and instructions for construction. The kit included thin carbon fiber rods and laser-cut wood pieces to optimize the weight of the helicopter and also included an extra rod attachable to the very tip of the top rotor to prevent the rotors from directly contacting the ceiling when flying (which could potentially damage the copter mid-flight). Due to the popularity of this kit design, I personally felt that much of the engineering spirit of the event became lost. Competitions saw team after team with identical designs come to fly, and the longest flight times ended up being awarded to the team that was able to make their helicopter the neatest. When the specifications (such as max rotor diameter and minimum helicopter weight) were changed between years, the kit would optimize accordingly. Teams who chose to deviate from the kit design and place faith in their own innovative abilities usually did not stand a chance.

However, come 2018, a very interesting new rule was applied that piqued my interest. Teams were given the option of either creating a traditional, single-axis helicopter or a chinook style helicopter. The catch was that times achieved with a chinook style copter would receive a 2.5x multiplier before being considered for final score. For those unfamiliar, this is what a Boeing CH-47 Chinook Helicopter is.

In contrast to the obvious upside of a huge multiplier, the downsides of using a Chinook Style helicopter are actually quite subtle. From a first glance, it is difficult to say why simply splitting the single-axis helicopter in half and placing the rotors side by side would cause flight times to take a huge hit, yet it does. The handicap from making a Chinook style can be summed up in 3 points. Each point leads nicely to the next.

- The stability problem

- Extra weight

- Less stored power

Stability is the most glaring initial problem. First and foremost, creating a single helicopter with two rotor axes requires there to be some kind of connection between the two axes. Otherwise, the helicopter would become two separate (and dysfunctional) helicopters. Thus, I added a simple X-truss made of thin balsa to create the connection. Secondly, due to the nature of having both rotors on the top of the helicopter, the center of gravity of the entire system is not as ideal as the single-axis helicopter. In order to prevent the helicopter from swaying off course from the ideal vertical flight direction, some kind of resistance needed to be in place. The theory behind this is very similar to why arrows are tipped with feathers or rockets require fins. Thus, sheets of Mylar were coated over the middle X-truss to create Left/Right air resistance while not impacting the freedom of Up/Down motion. Finally, it is almost intuitive that symmetry must be preserved when creating the Chinook-style helicopter. If not for the reason of weight balance (perhaps your helicopter has asymmetrical geometries but the center of mass is still preserved), then it may be for the reason of torque balance! To make the helicopter flies straight and stable, the two rotors must be generating EQUAL amounts of lift force. Otherwise, one side accelerates faster than the other and the helicopter begins flying sideways. Assuming the two rotors are identical, difference in lift force is dependent solely on difference in rotor torque, which comes from the twisted rubber band. Subsequently, since there are two rotor axes now, there must also be two separate rubber bands. The factors that go into the amount of torque generated by the rubber band are the elasticity and length of the band, the number of twists, and the length it needs to span. The first two factors are independent of the geometry of the helicopter itself, but in order to keep the spanning length of the rubber band constant, the two axes must also have the same length. This justifies the necessity for design symmetry.

It should come as no surprise, but the addition of the X-truss and Mylar film in between the two rotor axes will serve to add more weight onto the helicopter. I have not even considered the addition of the extra spacer to keep the second rotor from hitting the ceiling as well. It should also come as no surprise that extra weight reduces flight time. From my experience, weight is by far the most significant factor of flight time. Consequently, I needed to find a way to shave off the extra weight that I just added to my helicopter so that it dropped back down to its original weight as a single-axis. Frankly there were not that many options. The most logical places to shave weight off were the spacers on top, but unfortunately the specifications on the spacers are outlined strictly by the Science Olympiad rulebook. With not much to shave off on the rotors without completely redesigning them, I had to shave length off of the two rotor axes. No big deal right? Well this all culminated to the biggest culprit in reduced flight time.

As mentioned earlier, the length of the rotor axes have an effect on the total rotational energy storable within the rubber bands. When the rotation axis is longer, it allows more room for the rubber bands to span across, and thus the band loop itself can be larger. The larger the rubber band loop, the more twists it can store without snapping. The principle is analogous to a spring. Even with the same elastic properties, a short spring will never be able to stretch as long as a longer spring without deforming. The longer spring stores more energy, just as the larger band loop will store more energy in the form of a higher number of winds. Looking back at my Chinook copter, the length of the two rotor axes now were even less than half the length of the original single-axis helicopter! Keep in mind, I chopped the original in half, then shaved an additional length off to make weight. This was a scary realization. The cold hard truth was that this Chinook-style helicopter just had no way of storing the same number of rotor turns as the original. And that is the tragedy of the Chinook variant.

Nonetheless, I ended up making the right choice going for the multiplier with the Chinook design. Many teams I observed at competitions that year came with a similar mindset and willingness to try something new. Despite the very quick development of a new kit in the market, I constructed my design prior to the existence of the kit. For that brief time window, I was truly innovating! I felt value return to this engineering event. Sure, my crude design ended up being no match for the perfectionist design of the kit-makers, but at least I was being original.

Flight Recording