Three-Dimensional Modeling for Design

The entire scope of this course can be summed up in one word: Solidworks. Engineering 26 is a general engineering course which teaches students how to use the holy grail of all CAD software. This was the most practical course I took freshman year, and perhaps will be one of the most practical courses I will take as a Mech E undergrad.

Previously, I had only heard of CAD, but never found a reason to learn CAD myself. In fact, my attitude as an engineer was just to make everything manually from scratch using scrap material I found around home and some basic tools. If it worked, I couldn’t care less. I was a cheapskate engineer. For that reason, many of my builds, however well they functioned, could be considered atrociously messy engineering. “A PVC pipe will do” or “Sure, I can just use a cable tie instead” were common thoughts in my head when building. Occasionally, I would need a single part that required some customizability. When that was the case, I would outsource my CAD requests to a friend or colleague who knew how to CAD and had access to a 3-D printer. One would think that this would motivate me to learn CAD myself, but the truth was that these custom pieces were so rare that it did not seem a worthy investment of my time and effort to learn. Eventually, E26 came along and I was finally externally driven to learn CAD, and boy do I wish I learned earlier.

E26 is formatted in a way where each weekly homework or lab is designed to teach you a new basic skill in Solidworks. For example, week 1 might be basic 2-D sketching, week 2 might be extrusion, week 3 sweeps, etc. For this reason, lecture is practically pointless. Most of value from this class comes from knowing how to use a high-level software such as Solidworks, which only comes through practice. For the same reason, lab attendance and homework completion was critical. GSIs were a great resource to ask technical questions rather than having to sift through the endless expanse of the Solidworks help forums. Homework was where the practice happened. Each week, engineering sketches with exact dimensions were presented in the homework document and our job was to recreate each component as accurately as possible. Both volume and visual similarity were used as grading metrics.

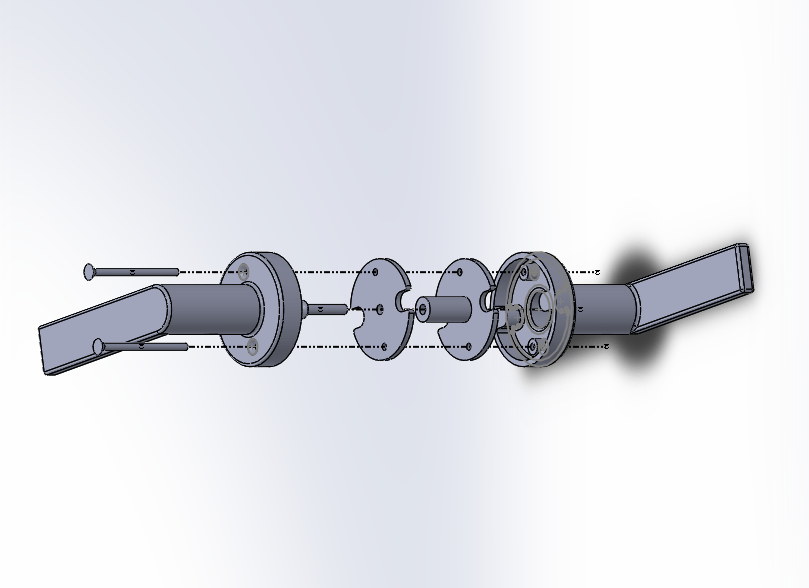

My favorite assignment from E26 was the doorknob assembly we were assigned to recreate near the end of the semester. This assignment brought together all the basic skills we had learned throughout the semester. Each component had to be individually created, and all components were geometrically mated together in the final assembly. The doorknob project could be considered a soft replacement to the capstone project that we never had. The final class project was supposed to be a self-designed wind turbine that was to be printed and tested (a project right up my alley considering my experience with wind turbine design). Unfortunately, COVID-19 cut the semester off short.

Regardless of how bitter I was over a lackluster and incomplete final project, E26 helped me realize the power and versatility of Solidworks and frankly, CAD in general. And there is still so much I do not know! Even now, new functionality discoveries within Solidworks continue to surprise me. Next stop: ANSYS!

On top of teaching me the ins and outs of Solidworks, the class helped make me a “smarter” engineer. I learned to be patient with my work. I learned to brainstorm and design before I executed. Most importantly, I learned to appreciate and leverage existing technology instead always making everything manually from scratch. Why waste the cumulative knowledge and progress of humanity? After all, the inventor of the car did not have to reinvent the wheel.

Food For Thought

What is the name of this odd gear system (Designed using Solidworks, not original design)? Where is it most commonly used?